Discover how vision can improve your production & quality processes.

Types Of Machine Vision Systems

-

2-D

2D vision systems benefit manufacturing companies by enabling automated inspection, guiding assembly robots, tracking parts, and sorting products. These systems enhance quality control by quickly identifying defects, minimizing errors, and ensuring consistent product quality.

-

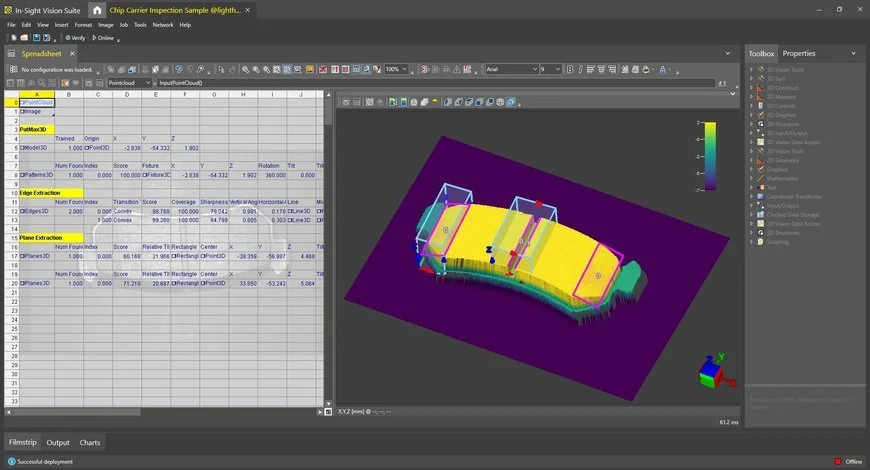

3-D

3D vision systems provide significant advantages in manufacturing by enabling more precise robotic guidance, intricate part manipulation, and advanced quality control. These systems can accurately measure complex shapes and orientations, allowing for precise bin picking, flexible assembly processes, and the detection of subtle defects that 2D systems might miss

-

Barcode Readers

Barcode readers enhance manufacturing efficiency and accuracy across various applications. Types of barcode readers include:

Handheld readers provide flexibility for mobile inspections and inventory management

Fixed-Mount systems automate data capture at specific points in the production line.

Verifiers ensure barcode quality and readability, , minimizing errors and preventing disruptions to the supply chain.

Vision systems are sophisticated technologies that enable machines to "see" and "understand" the world around them. They leverage cameras and advanced image processing algorithms to perform a wide range of tasks, including:

Feature Recognition: Identifying and classifying specific objects or patterns within an image. This includes recognizing shapes (circles, squares, triangles), colors, textures, and even subtle variations in appearance.

Reading: Extracting text from images, such as barcodes, OCR (Optical Character Recognition) for printed or handwritten text, and interpreting characters in different fonts and orientations.

Counting: Accurately determining the number of objects within a specific area of an image. This can be used for inventory management, quality control, and other applications where precise quantity tracking is crucial.

Inspection: Examining objects for defects, inconsistencies, or deviations from predefined standards. This can involve detecting scratches, dents, missing parts, or variations in size and shape, including defects as small as 5 microns in depth, ensuring product quality and consistency.

Vision systems find applications in various industries, including manufacturing, automotive, healthcare, logistics, and retail. They play a critical role in automating processes, improving efficiency, enhancing quality control, and ensuring safety.

Have any questions?

Contact us to discuss how machine vision can enhance your application’s performance.